Monomaterial and circular economy

In recent years, the concept of circular economy has received increasing attention in the context of sustainability. This is the idea of using resources for as long as possible and minimizing waste by reusing, recycling and reusing materials. The circular economy can help ease the strain on natural resources and reduce the environmental impact of production and consumption. An important aspect of the circular economy that accompanies us in our daily activities is the application of the mono-material approach to product design and manufacture.

What does mono material mean?

The mono-material concept refers to products that consist of a single material, as opposed to multi-material products that can be composed of several different materials. For example, in clothing, a multi-material product would be a mix of synthetics, cotton, viscose, and metal.

Mono-material products can be more easily recycled and reused, making them a valuable resource in circular systems. The mono-material approach means that products can be dismantled and sorted more easily, which greatly facilitates the recycling process and reduces waste. This is in contrast to multi-material products, which can be difficult and very expensive to recycle.

Challenges of monomaterial design

Despite the benefits of mono-material design, there are also challenges associated with this approach. A major challenge is the difficulty of finding suitable mono-material alternatives to existing products. For example, many products are made from multiple materials for cost, functionality, and aesthetics. Switching to mono-materials can require significant design changes and can be expensive, which can discourage companies from taking this approach.

The complexity of mono-material products lies primarily in the design and implementation. The materials must be chosen in such a way that they are not only recyclable, but also guarantee the necessary functionality and quality. In addition, not only the respective individual piece has to correspond to this concept, but the entire product.

Unfortunately, there is still little awareness of the potential and opportunities of mono-material products and many shy away from the complexity and effort involved.

Opportunities and potential

Despite the complexity and the challenges, we mainly see opportunities and exciting solutions in connection with mono-material products. One of the main benefits is the potential for greater resource efficiency and less waste. The use of mono-materials allows products to be designed for easy disassembly and recycling, which can help minimize the amount of waste and extend the life of materials.

Another opportunity is the potential for innovation and improved product design. Favoring mono-materials can force designers and developers to think more creatively about the materials and processes used, which can lead to more sustainable and innovative solutions.

In recent years, the number of companies dedicated to the development of circular solutions has increased rapidly. This ranges from the development of bioplastics and other renewable materials that are easier to recycle, to new recycling technologies and infrastructure to recycle the materials used.

Overall, mono-materials are a good solution to promote circular economy and reduce waste. By designing products to be more easily dismantled and recycled, companies can help reduce the environmental impact of their products while improving resource efficiency. While mono-material design presents some challenges, the potential benefits make it an important approach to promote more sustainable and circular products.

Our mono-material solutions

At Muntagnard, we have the ambition to be a pioneer and Thinking products further down to the smallest detail, whereby we always try to reduce the materials used to an absolute minimum. This results in both new interpretations of traditional concepts and completely new innovations.

T-shirts made from actually only 1 material

Even if a T-shirt says 100% on it, it's usually not 100%. The washing labels, labels and the sewing thread, for example, do not have to be declared and are usually made of polyester, i.e. plastic. An ordinary T-shirt uses a good 100m of sewing thread. That's why we don't rely on 100m of additional plastic, but always use the same material for the sewing thread as for the main fabric.

MANGOLA T-shirt made from premium cotton

MIUtec C-shirt made of functional fibers

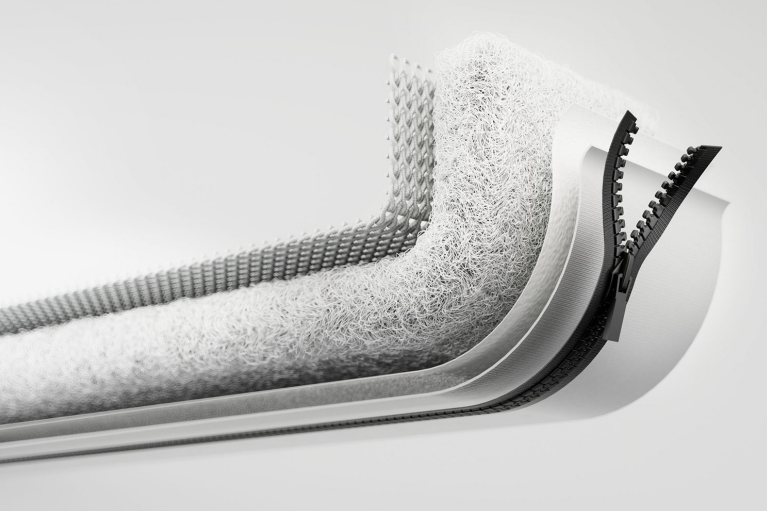

Only 2 materials in 1 jacket

With the MIUtec Iso jacket, for example, only two different materials are used for the entire jacket. The fabric, sewing thread and even the entire zip fastener are all made from the same raw material. Only the insulation made of wood fibers is a different material, which can be separated more easily in the recycling process. Thanks to this innovative design concept, the jacket received two awards from ISPO.

Less is not always better

Even if the statements made so far could indicate that we are absolute advocates of the fact that only mono-material products should be produced, this is by no means the case. It doesn't always make sense to rely on just one material, and a material mix can certainly have its justification for numerous applications and products.In summary, mono-materials play a crucial role in the transition to a circular economy as they simplify the recycling process and promote resource efficiency. However, the realization of mono-material products requires careful consideration of design and material properties. On the way to a more sustainable future, the mono-material approach is an important piece of the puzzle in a circular economy, but it is by no means to be seen as a one-size-fits-all solution.